|

SHENZHEN GOLDSOURCE MACHINING CO.,LTD

|

Gold Index: 10883

You are here: home > Aerospace / Auotmotive Swiss Screw Machining With Steel , Aluminum , Plastic

Aerospace / Auotmotive Swiss Screw Machining With Steel , Aluminum , Plastic

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GS-S-72

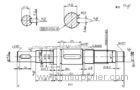

Aerospace / Auotmotive Swiss Screw Machining With Steel , Aluminum , Plastic

<

Aerospace / Auotmotive Swiss Screw Machining With Steel , Aluminum , Plastic

Quick Detail:

- Materials option includes wild steel, aluminum alloy, copper, brass, Zamak, stainless steel, plastic etc;

- Swiss type machines are actually an automatic lathe for machining such parts with round shapes;

- Surface finish can be anodized, passivated, electroplating or even powder coated;

- For Swiss/screw machining parts, the shape and requirements are typically simple, but the tolerances may be very tight;

- Final dimensions fully checked by our QA people before shipping, no compromise on quality;

- Roughness and hardness as per the prints or even better;

- We can support your prototypes development, please contact us;

- Flatness, parallelism, perpendicularity, roundness to be 0.05mm or less.

Description:

- Swiss type screw machines are used to machine typically cylindrical, threaded parts in high volume, with a wide range of material options.

- As there are multiple spindles on the machine, most of the work can be done on the machine so there’s no additional machining work required after it comes out from the machine.

- Products like screws, bolts, nuts, bushings, pins, studs etc are using this kind of process. We have state of the art CNC screw machines and the products are very precise.

- For high volume parts, the material bars can be fed to the lathes automatically, and the machine will do the pre-coded processes and cut the bar one (part) after another.

- Perfect heat treatment process.

- Surface polished or grinded.

Applications:

- Defense, auotmotive;

- Telecommunication, consumer electronics;

- Industrial equipments, medical device;

- Aerospace, oil and gas;

- Infrastructure and processing equipments, gear motors etc.

Specifications :

| 1) Material | Wild steel, carbon steel, aluminum alloy, copper, brass, bronze, Zamak, stainless steel, ABS, PA, POM etc |

| 2) Finishing and Treatment | Shot blasted, anodized, electroplating, passivated, painted or powder coated, quench and temper, annealing etc |

| 3) Equipments involved | Swiss/Screw machines |

| 4) Processes involved | CNC turning, drilling, tapping, boring, grinding |

| 5) Dimensional tolerance | ±0.02mm or less |

| 6) Geometric tolerance | ±0.03mm or less |

| 7) Roughness | Ra 0.05 or less |

| 8) Production capacity | 10,000pcs per month |

| 9) Quality inspection | IQC, PQC, FQC |

| 10) Lead time | 30 days |

| 11) Place of delivery | Shenzhen, China |

Competitive advantages:

- Adhere to specification, quick response, fast delivery;

- Cost effective, quality guaranteed;

- Good at making small parts less than 10mm in diameter;

- Comprehensive machining processes and knowledge of finishing, treatment requirements,

- Experienced people for various machining processes;

- Our turning/milling centers can produce parts with most complicated features and highest precision;

- PPAP for parts.

Related Search

Aluminum Machining

Aluminum Screw

Stainless Steel Machining Parts

Stainless Steel Machining

Steel Machining Part

Stainless Steel Casting Machining

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

SHENZHEN GOLDSOURCE MACHINING CO.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)