|

SHENZHEN GOLDSOURCE MACHINING CO.,LTD

|

Gold Index: 10883

You are here: home > Aluminum 6061-T6 Precision Machining Services For Missiles , Marines , Submarines

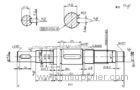

Aluminum 6061-T6 Precision Machining Services For Missiles , Marines , Submarines

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GS-H-34

Aluminum 6061-T6 Precision Machining Services For Missiles , Marines , Submarines

&n

Aluminum 6061-T6 Precision Machining Services For Missiles , Marines , Submarines

Quick Detail:

- Used on Missiles;

- Comprehensive machining processes involved, including CNC turning, CNC milling, surface grinding, cylindrical grinding, boring, Wire EDM, drilling, tapping etc;

- Surface polished or grinded;

- Roughness Ra 1.6;

- Passivation treatment applied;

- Material is AA6061-T6;

- Hardness NA;

- Final dimensions and other requirements fully checked by our QA people before shipping, quality guaranteed.

- Flatness, parallelism, perpendicularity, roundness to be 0.06mm or less.

Description:

- Major processes are CNC turning, grinding, boring and CNC milling;

- Parts are customed for customers as per requirements;

- For military use;

- Tight tolerances;

- Parts are hardened, tempered or anodized as per drawings;

- Dimensions and other requirements are fully checked.

Applications:

Parts are applied for:

- Defense, Marines , Submarines

- Medical device, aerospace, food and beverage processing equipments.

Specifications :

| 1) Material | Aluminum alloy 6061-T6 |

| 2) Finishing and Treatment | Polishing, grinding, passivation, anodizing |

| 3) Equipments involved | CNC machining/milling center, CNC lathe, surface grinding machine, boring machine etc |

| 4) Processes involved | CNC milling, turning, boring, tapping, grinding etc |

| 5) Dimensional tolerance | ±0.012mm or less |

| 6) Geometric tolerance | ±0.025mm or less |

| 7) Roughness | Ra 0.020 or less |

| 8) Production capacity | 10,000pcs per month |

| 9) Quality inspection | IQC, PQC, FQC |

| 10) Lead time | 30 days |

| 11) Place of delivery | Shenzhen, China |

Competitive advantages:

- Adhere to specification;

- Quick response, fast delivery;

- Cost effective;

- Quality inspected and guaranteed;

- Chrome passivation capability.

Related Search

Precision Machining

Aluminum Machining

Cnc Precision Machining

Precision Cnc Machining

Cnc Precision Machining Part

Precision Machining Part

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

SHENZHEN GOLDSOURCE MACHINING CO.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)