|

SHENZHEN GOLDSOURCE MACHINING CO.,LTD

|

Gold Index: 10883

You are here: home > Electroplating Or Painted Quick Turn Machining For Processing Equipments

Electroplating Or Painted Quick Turn Machining For Processing Equipments

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GS-T-316

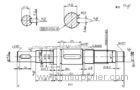

Electroplating Or Painted Quick Turn Machining For Processing Equipments

Electroplating Or Painted Quick Turn Machining For Processing Equipments

Quick Detail:

- Materials option includes wild steel, tool steel, aluminum alloy, copper, brass, Zamak, stainless steel, plastic, Kovar etc;

- CNC turning is the main process for such parts with round shapes;

- Surface finish can be anodized, passivated, electroplating or even powder coated;

- For quick turn parts, the shape and requirements are typically simple;

- Final dimensions fully checked by our QA people before shipping, no compromise on quality;

- Roughness and hardness as per the prints or even better;

- We can support your prototypes development, please contact us;

- Flatness, parallelism, perpendicularity, roundness to be 0.05mm or less.

Description:

- CNC turning is such a process, mainly employed to machine parts with round shapes.

- We call the machine which does the turning process a lathe.

- Nowadays most of our lathes are with CNC system.

- We also have some conventional lathes.

- Turning process is very common one as we can see round parts everywhere.

- For high volume parts, the material bars can be fed to the lathes automatically, and the machine will do the pre-coded processes and cut the bar one (part) after another.

- Perfect heat treatment process.

- Surface polished or grinded.

Applications:

- Defense, auotmotive;

- Telecommunication, consumer electronics;

- Industrial equipments, medical device;

- Aerospace, oil and gas;

- Lighting;

- Infrastructure and processing equipments, gear motors etc.

Specifications :

| 1) Material | Wild steel, tool steel, aluminum alloy, copper, brass, bronze, Zamak, stainless steel, ABS, PA, POM, Kovar, Invar etc |

| 2) Finishing and Treatment | Shot blasted, anodized, electroplating, passivated, painted or powder coated, quench and temper, annealing etc |

| 3) Equipments involved | CNC machining/milling center, CNC boring center, surface grinding, cylindrical grinding, wire EDM, tapping machine etc |

| 4) Processes involved | CNC milling, drilling, tapping, boring, grinding |

| 5) Dimensional tolerance | ±0.02mm or less |

| 6) Geometric tolerance | ±0.05mm or less |

| 7) Roughness | Ra 0.08 or less |

| 8) Production capacity | 10,000pcs per month |

| 9) Quality inspection | IQC, PQC, FQC |

| 10) Lead time | 30 days |

| 11) Place of delivery | Shenzhen, China |

Competitive advantages:

- Adhere to specification, quick response, fast delivery;

- Cost effective, quality guaranteed;

- Comprehensive machining processes and knowledge of finishing, treatment requirements,

- Experienced people for various machining processes;

- Our turning/milling centers can produce parts with most complicated features and highest precision;

- PPAP for parts.

Related Search

Equipments

Electroplating Chrome

Medical Equipments

Electrical Equipments

Dental Equipments

Garden Equipments

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

SHENZHEN GOLDSOURCE MACHINING CO.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)