|

SHENZHEN GOLDSOURCE MACHINING CO.,LTD

|

Gold Index: 10883

You are here: home > High Precision Stainless Steel Military Machining With Anodized Surface

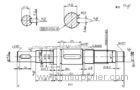

High Precision Stainless Steel Military Machining With Anodized Surface

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GS-M-12

High Precision Stainless Steel Military Machining With Anodized Surface

High Precision Stainless Steel Military Machining With Anodized Surface

Quick Detail:

- Materials option includes wild steel, tool steel, aluminum alloy, copper, brass, Zamak, stainless steel, plastic, Kovar etc;

- Any machining process can be involved to produce your custom parts as needed like CNC turning, CNC milling, surface grinding, cylindrical grinding, optical grinding, CNC boring, Wire EDM, drilling, tapping and honing etc;

- Surface finish can be anodized, passivated, electroplating, chromatization and many more;

- Final dimensions and other requirements fully checked by our QA people before shipping, quality guaranteed;

- Roughness and geometric tolerances etc as per the prints or even better.

Description:

- Parts are machined from a block of material, which may require crack detection before machining, like ultrasonic testing, xray/γray testing etc. We have experience in those;

- These parts may involve very complicated processes including turning, milling, boring, wire EDM, polishing, honing etc;

- With 30% plus of our sales turnover from Chinese Army and its subcontractors, we have rich experiences in machining parts for the defense and military industries.

- We machine many parts for missiles and artilleries every year. These parts need to pay very high attention because customers require zero defect.

- We will be very happy to quote to you if you send us specifications and requirements if you demand parts for defense and military industries.

Applications:

- Defense and military industry etc.

Specifications :

| 1) Material | Wild steel, tool steel, aluminum alloy, copper, brass, bronze, Zamak, stainless steel, plastic, Kovar, sheet metal etc |

| 2) Finishing and Treatment | Shot blasted, anodized, electroplating, passivated, chromatization, painted or powder coated, quench and temper, annealing etc |

| 3) Equipments involved | CNC machining/milling center, CNC turning, CNC boring center, surface grinding, cylindrical grinding, wire EDM, tapping machine etc |

| 4) Processes involved | CNC milling, drilling, tapping, boring, grinding, polishing, honing etc |

| 5) Dimensional tolerance | ±0.002mm or less |

| 6) Geometric tolerance | ±0.005mm or less |

| 7) Roughness | Ra 0.025 or less |

| 8) Production capacity | 10,000pcs per month |

| 9) Quality inspection | IQC, PQC, FQC |

| 10) Lead time | 30 days |

| 11) Place of delivery | Shenzhen, China |

Competitive advantages:

- There are not so many suppliers in China who can commit to your requirements in defense and military industry and we believe we are the most competitive among them, in terms of cost, quality, capabilities etc.

- Parts are fully checked at every step;

- Our best machines, most experienced staff will handle your needs and we are sure you will be satisfied.

Related Search

Stainless Steel Machining Parts

Stainless Steel Machining

Stainless Steel Casting Machining

Precision Machining

Stainless Steel Precision Castings

Precision Stainless Steel Shaft

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

SHENZHEN GOLDSOURCE MACHINING CO.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)