|

SHENZHEN GOLDSOURCE MACHINING CO.,LTD

|

Gold Index: 10883

You are here: home > Aircrafts Aluminum 7075 CNC Custom Machining Parts With CNC Machining / Milling Center

Aircrafts Aluminum 7075 CNC Custom Machining Parts With CNC Machining / Milling Center

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GS-G-117

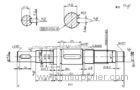

Aircrafts Aluminum 7075 CNC Custom Machining Parts With CNC Machining / Milling Center

</

Aircrafts Aluminum 7075 CNC Custom Machining Parts With CNC Machining / Milling Center

Quick Detail:

- For aircrafts, UAVs;

- Flatness, parallelism, perpendicularity, roundness to be 0.03mm or less;

- Materials option includes AA2014, AA7075, AA2017 etc;

- Comprehensive machining processes involved, including CNC turning, CNC milling, surface grinding, cylindrical grinding, boring, Wire EDM, drilling, tapping etc;

- Roughness Ra 1.6;

- Surface polished or grinded;

- Passivation treatment applied;

- CMM report to be presented before shipping.

Description:

- Respect of the drawings/requirements;

- Machined from forged, block of aluminum alloy;

- Such processes like CNC turning, boring, grinding and CNC milling are involved;

- Tight tolerances as per military standards;

- Parts are passivated, chromated, tempered or anodized as per drawings;

- Top capabilities in China.

Applications:

Parts are applied for:

- Military, aircrafts;

- Aerospace, Medical device;

- Special equipments.

Specifications :

| 1) Material | AA2014, AA7075, AA2017 etc; |

| 2) Finishing and Treatment | Anodizing, polishing, grinding, passivation etc |

| 3) Equipments involved | CNC lathe, CNC machining/milling center, CNC boring machine, 4 and 5 axis CNC centers etc |

| 4) Processes involved | CNC milling, turning, boring, grinding etc |

| 5) Dimensional tolerance | ±0.02mm or less |

| 6) Geometric tolerance | ±0.05mm or less |

| 7) Roughness | Ra 0.016 or less |

| 8) Production capacity | 100pcs per month |

| 9) Quality inspection | IQC, PQC, FQC |

| 10) Lead time | 30 days |

| 11) Place of delivery | Shenzhen, China |

Competitive advantages:

- Insertion of heli-coils;

- Overall specifications are hard to meet but we can do;

- Wide range of materials option;

- Cost effective;

- Quality guaranteed as soon as we take the order;

- Our comprehensive machining processes and knowledge of finishing, treatment requirements etc will make you eased.

Related Search

Cnc Machining Center

CNC Machining Parts

CNC Machining

Cnc Milling Center

Cnc Precision Machining

Precision Cnc Machining

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

SHENZHEN GOLDSOURCE MACHINING CO.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)